Transducers

UBERTONE offers a large choice of ultrasonic transducers specially dedicated to measurements in liquids. We manufacture our own transducers in our workshop, which allows full control of the production method, custom design and shorter delivery time.

Advantages

- controlled production method

- narrow or wide bandwidth

- standard or high temperature transducers

- custom design possible

The manufacturing of our ultrasonic transducers is based on an innovative piezoelectric technology with composite structure giving them a wide bandwidth as well as a high sensitivity and a high signal-to-noise ratio. Our quality control includes the unit's individual electro-acoustic testing after manufacturing. This allows us to precisely know the bandwidth and efficiency of each transducer that we sell or integrate.

With these transducers, it is possible to measure directly in contact with the liquid or through a wall (see FAQ - Can I measure through a wall?). Measuring through the air is not possible with our transducers (see FAQ - Can our devices measure in air?), thus when measuring through a wall, there should be no air between the transducer surface and the wall. To ensure this, the simplest way is to use acoustic transmission gel.

See also:

In consultation with the user, we will provide the probe that best suits the application. Indeed, the nature of the fluid, the nature and grain size of the acoustic scatterers, the constraints (high temperature, high pressure, corrosion resistance, food standards, etc.), both depth and velocity ranges, and spatial resolution will guide the selection of the most appropriate transducer.

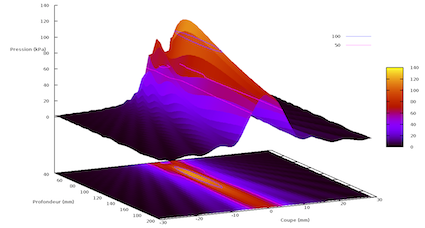

We can provide a study to simulate quickly and accurately the form of an acoustic beam in the receiving environment. The numerical code developed by UBERTONE, integrates various functions of transmitted waves (pulse, sine, etc.) and allows the active surface to take any shape.

Contact us for more information.

Here is the list of our standard transducers:

| Central frequency (MHz) | 0.5 | 1.0 | 3.0 | 3.0 |

|---|---|---|---|---|

| Active diameter (mm) | 35 | 20 | 7 | 7 |

| Velocity measurement over a range up to (m) | 8.0 | 3.0 | 1.0 | 1.0 |

| Acoustic turbidity measurement over a range (m) | [0.30; 15] | [0.20; 6] | [0.10; 2] | [0.10; 2] |

| Minimal scatterers size (µm) | 200 | 100 | 35 | 35 |

| Maximal temperature (°C) | 40 | 110 | ||

We can offer custom designed transducers, with central frequency possible within [0.2; 9]MHz

The integration of the transducers into a given setup is sometimes an issue. But being often confronted with this, we have developed a large experience in the design of transducer holders.

In case of a setup equipped with an aluminium profile system (like MiniTec, Bosch Rexroth ...), we can provide any kind of transducer holder with any tilt angle either for measuring through a wall or directly in the liquid.

The example beside shows 3 MHz transducer holder with a 70° angle allowing measurement through the PVC wall of a channel at different positions, by translation along an aluminium profile.

When dealing with bistatic measurements, the relative position of the two transducers depends on the measurement range to be achieved. Depending on the setup and application, we can offer a holder for bistatic measurements, where the angles and positions of the transducers can be designed upon request. The attached photo shows a holder for three transducers measuring at 1MHz: one classic narrow beam emitter and 1 pair of large beam receivers. The holder can be connected to standard camera holders, such as suction cup systems, for a quick and adaptive installation.

When working in channels or tanks, it is possible to measure through the wall. Holding the transducer to a structure or drilling a hole into the wall may not be possible. Ubertone has designed a holder with a suction cup. It can easily be fixed on any kind of smooth and flat surface (glass, plastic…). The holder shown on the photos below is made for our 3 MHz transducers.

Depending on your setup, you are welcome to contact us and we will be very happy to think together about a custom-made solution for you.

Technical datasheets on request.